will be 3.69 93.73 mm and a.09 2.29 mm radius needs to be added to the corners. I was thinking if I could find a bearing with the right inner and out diameter could I just shove it on the shaft and use it like a poor man's templating bit? It doesn't feel like too crazy of an idea.Īn alternate option would be a guide bushing which is probably where I would end up going with this but I don't think they really have those for router tables which means I would have to do it holding the router which I'm botnure I'm comfortable doing with such a large bit. The system is able to house up to 300 tools and 600 dies providing the. Alternatively if the bit that did both tracks at once were a template bit I would just make it on the router table. I could use the single track bit and devise some jig to attack to the router base that would reduce the contact area allowing it to reach the inside of the curve. A single one used for making curves and a double one for strait track.

There are two different bits for the track groove. But then I saw bridges like the one in this set and I fell in love but can't decide the best way to approach it. įor the most part it's pretty straight forward. For Christmas my wife got me a set of router but to make Brio style tracks. Once you create a special or cluster tool and add it to a tool inventory, you can use the Place Tool Hits option on the Group Pattern submenu (Draw menu) to. Long version: I always wanted to make my so a wooden train set. Am I able to add a bearing to the shank to make a poor man's templating bit. There are not versions of the bit available with bearings. Tldr: I have a specialty router bit that I would like to use with a template. No top-level wood ID, low effort, or price queries Manufactured with copper wires with bullet terminals that are over-molded with black PVC. Weather resistant to work with any trailer or electrical application. No memes, image macros, reaction gifs/videos, etc. 24 inch, 4 way, molded connector loop made with 18 gauge wire. Projects related to firearms, religion, or flags will be allowed but locked. Includes but not limited to religious and political topics. No reposts, rehosted, or freebooted content. go to for a detailed explanation of the rules.ĭon’t be rude. Before posting, check that your content doesn't violate the rules below. r/woodworking is a forum that encourages the respectful exchange of woodworking knowledge and projects.

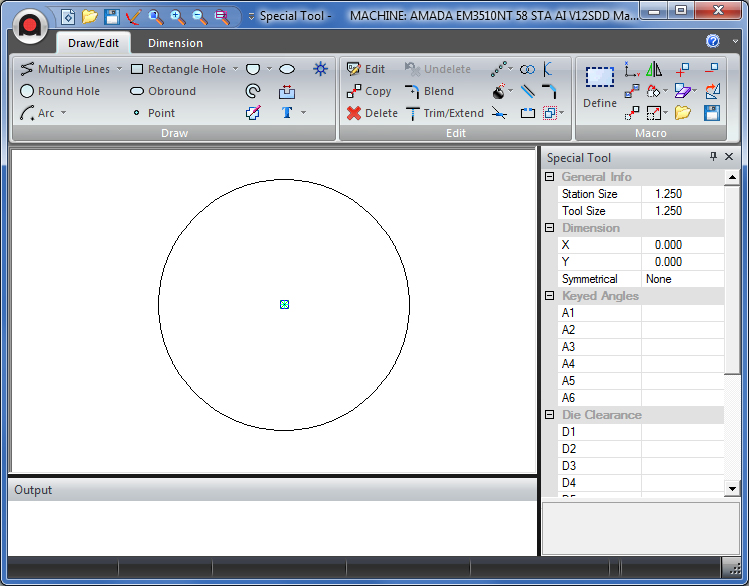

It IS under reconstruction right now, so we apologize for broken links, etc. "How do I start?") and links to many valuable resources. With our optional FabriBEND module, you can simulate the bending process, reducing the need for costly and time consuming prototypes.įabriWIN will streamline your design to manufacturing processes, maximizing the performance, productivity and profitability of your fabrication operations.BEFORE ASKING A QUESTION, DID YOU READ OUR WIKI? Our Wiki includes answers to common questions (e.g. You can optimize material utilization with our optional IntelliNEST Nesting and Scheduling module.

Adding a 4way radius tool to fabriwin code#

FabriWIN will generate programming code faster and more efficiently for all of your punching, cutting and combination machines. Cutting attributes, conditions, lead-ins and lead-outs are also automatic. A large pool of experienced FabriWIN programmers assures the maximum flexibility in hiring and minimum training of your personnel.įabriWIN eliminates time-consuming programming processes with Automatic Tool selection, sheet layout and sequence optimization.

Adding a 4way radius tool to fabriwin software#

Compatible across all makes and models of both punching and cutting machines, you can match software functionality and cost to your machine's capability. Capable of reading all industry standard CAD files, FabriWIN ensures that you will be able to meet your client's requirements. With over 6,000 user licenses worldwide, FabriWIN's large installed user base assures the greatest return on investment among all CAD/CAM products.įabriWIN utilizes a built-in 2D CAD system with sheet metal specific logic and direct integration to best of class 3D Solid Modeling packages. FabriWIN provides a mature and stable software environment that you can rely on. Metalsoft : Sheet metal software, CADCAM, Quoting & Production control SoftwareįabriWIN is the most widely used CAD/CAM package available for metal fabrication and the industry leading solution for programming Punching, Laser, WaterJet, Plasma and Combination Punch Cut CNC machines.

0 kommentar(er)

0 kommentar(er)